- Company

- Technology

Technology

The data storage industry depends primarily upon the principles embodied in the field of magnetics to store and subsequently retrieve the vast amount of information used by the computing industry. Magnetic recording employs the use of "hard" magnetic materials to store information. Hard magnetic materials are materials that require strong magnetic fields to orient the direction of magnetization within the material. These materials, once oriented, permanently retain this magnetic orientation until they are reoriented by another strong magnetic field.

Early magnetic recording heads employed the principle of induction to read and write data on magnetic disks. The principle of induction defines a relationship between magnetism and electricity. When a magnetic material is wrapped with a coil of an electric conductor, such as copper, magnetic fields are produced when an electric current is passed through the copper conductor. Conversely, when the magnetic material passes by a magnetic field, an electric current is induced in the copper conductor. The inductive process is used to create the strong magnetic fields that orient the hard magnetic material on the surface of the recording disk. The reverse of this inductive process was also used for many years to read back the information stored on the surface of the disk. As areal densities approached 1.0 billion bits per inch, the inherent conflict of designing an element for both reading and writing increased.

Magneto-resistive technology derives its name from a class of materials that change resistance in the presence of a magnetic field. Magneto-resistive recording heads utilize an inductive write head based on the same inductive principles of earlier technologies combined with a magneto-resistive element to provide the read function. These magneto-resistive elements are designed and fabricated to provide many times the signal sensitivity or reading efficiency of the inductive read head technology. The inherent conflict of designing an element for both reading and writing is eliminated by enabling each element to be optimized for its unique purpose.

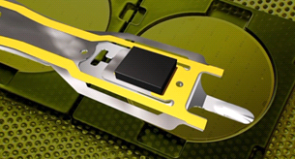

Giant magneto-resistive is an advanced application of magneto-resistive technology. By employing multiple layers of ultra thin films, giant magneto resistive heads are able to provide significantly higher signal output than conventional magneto resistive heads. The most common type of giant magneto resistive head is a spin valve sensor. In its simplest form, the spin valve consists of four film layers, a magnetic sensing layer, a non-magnetic metal spacer layer, a magnetic pinned layer and an exchange layer. The magnetic orientation of the pinned layer is fixed and held in place by the adjacent exchange layer, while the magnetic orientation of the sensing layer changes in response to the magnetic field from the disk. The level of electrical resistance of this multi-layer thin film sensor depends on the relative magnetic orientation of the sensor and pinned layer, yielding low resistance when they are in parallel state and high resistance at anti-parallel state. Giant magneto resistive recording heads provide significantly stronger signals than conventional magneto-resistive recording heads, enabling higher areal densities.